In previous articles, we have discussed the advantages of extruded products in animal feed, which we remind you of here:

- High stability in water and lower environmental pollution.

- Improved food digestibility

- High efficiency and high conversion rate

- Selection of food buoyancy

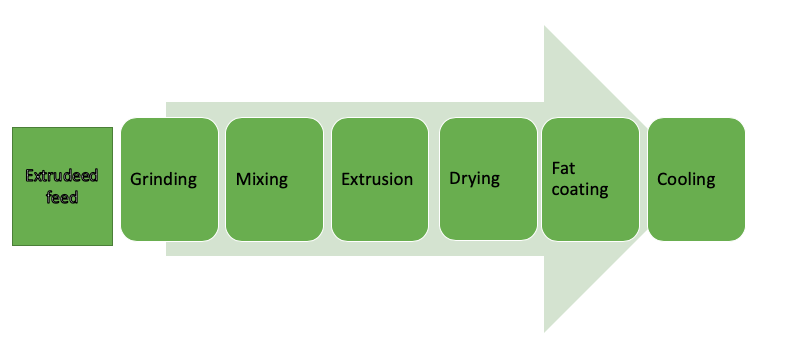

Today we want to show you the machinery and processes needed to obtain top-quality extruded feed like the kind Dibaq offers its customers.

In the above diagram, you can see the main steps in the manufacturing process of extruded feed, and below we’ll describe the main equipment involved in the process and its importance.

GRINDING

The raw materials that make up the feed arrive at the factories in different formats and grain sizes (cereals, flours, grain legumes, etc.). All of these elements must be ground to the proper particle size for subsequent mixing and ‘cooking’ with the extrusion process.

To carry out this process, the most common method is to use hammer mills. Generally, two mills are used in series in what is known as pre-grinding and grinding. With the right size, the materials are fed into the mixer.

MIXING

In this step, the ground materials are received to configure the right mixture of ingredients following the recipes developed by our animal nutrition experts. Usually mixers with paddle rotors are used to homogenise the mixture, thus ensuring the uniformity of the materials that will reach the extrusion section.

EXTRUSION

Conditioner. Intensive pre-conditioning is a decisive stage in the extrusion process. To prevent expansion of the pellets outside of the extruder, the ingredients must be kept at a set temperature.

Extruder. Extrusion is the most important phase, and it is a high-temperature process with short times, which minimises the degradation of the nutrients while improving the digestibility of starches and proteins. Extrusion is a process in which the feed is not only compacted but also ‘cooked’, and this requires high levels of humidity, temperature and pressure. All these requirements must be met to achieve the desired degree of expansion when it leaves the extruder. To conduct this process, single or twin-screw extruders are used to compress the materials, previously mixed, to guarantee the humidity and temperature conditions required to obtain a high-quality product. The extruder is fed continuously with the mixture of ingredients, and the screw or screws compress and cook this mixture. As it comes out of the extruder, this mixture is cut into cylinders of the desired thickness and length, depending on the species and growth stages for which the feed is intended.

DRYING

The food that comes out of the extruder still contains excess moisture due to the addition of water during pre-conditioning and extrusion. Therefore, drying is a mandatory process in order to maintain the stability of the moisture in the finished feed. Drying is carried out in large drying hoppers providing hot, dry air that eliminates moisture, in which the feed can move horizontally on a vibrating belt (horizontal dryers), or pass from one chamber to another vertically (vertical counterflow dryers).

FAT COATING

The purpose of the fat coating machines is to add liquids to the extruded products, mainly oils to increase their nutritional and energy value. In this case, a fat coating machine/vacuum mixer is used. By extracting air from the extruded pellet, it allows a higher degree of oil incorporation.

COOLING

Finally, the extruded product must be thermally stabilised, and for this purpose, it is placed in a vertical cooler that reduces its temperature with the counterflow circulation of room-temperature air.

From this point, the feed is ready to be packaged in different formats depending on the product and the target market. It is very important to bear in mind that all these processes and the associated machinery are supervised by our experts, and that the key to the quality of our products lies in both the raw materials used and the recipes prepared by our animal nutrition experts.